By dark of night, sea turtle hatchlings protected by advanced glass options

Throughout much of the world, sea turtles are getting ready to lay their eggs on beaches. Virtually unchanged for over 100 million years, sea turtles are some of the oldest creatures on Earth. Unfortunately, excessive coastal building and light from buildings at night have endangered the sea turtles’ nesting environment. Advanced glazing systems are one of the solutions that can help protect the delicate ecosystem on the beaches. The problem has to do with light at night. Female sea turtles bury their eggs on the beaches, and then return to the sea. When the babies hatch, the young turtles instinctively return to the ocean at night, guided by the moonlight reflecting on the ocean and bioluminescence. But when coastal development began, the brighter light came from buildings, confusing the babies, and often costing the lives of the young hatchlings when they were unable to find the ocean.

When the problem was discovered, many began to take action. The state of Florida, for example, developed a Model Lighting Ordinance for Marine Turtle Protection (1993), prohibiting light from having an adverse effect on nesting and hatching turtles. There have been recent updates to the ordinance, Chapter 62B-55, which went into effect in 2020.

“In marine turtle nesting areas, all forms of lighting shall be shielded or otherwise designed so as not to disturb marine turtles."

Commonly known as the turtle code, the ordinance states: “In marine turtle nesting areas, all forms of lighting shall be shielded or otherwise designed so as not to disturb marine turtles. Tinted glass or similar light control measures shall be used for windows and doors which are visible from the nesting areas of the beach.”

Blocking the light with curtains or blinds is one way to meet the requirement, but that diminishes the benefits and rationale for the glazing. Most visitors to the beach want to enjoy the views!

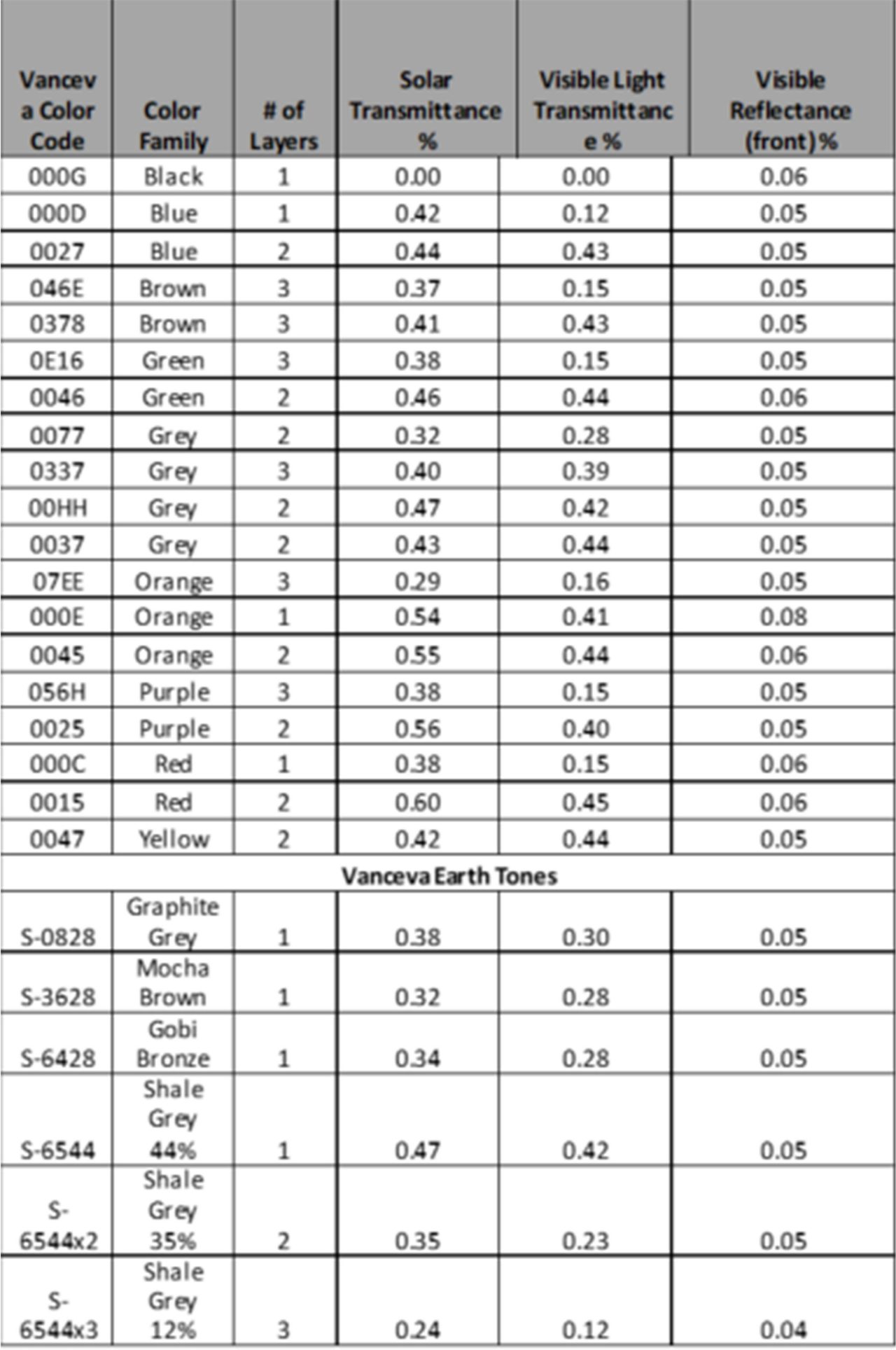

Another option is to install colored laminated glass in the buildings. Utilizing clear, coated, or tinted glass in the laminate construction with Saflex™ and Vanceva™ PVB interlayers provides an almost limitless palette and provides many choices in the look, feel and performance of the glazing. The use of colored interlayers can provide the necessary light reduction from the facility, so the light is reduced to designated levels deemed not to interfere with nesting and hatching of marine turtles. The use of colored interlayer can also reduce the glass thickness sometimes required when using tinted glass alone.

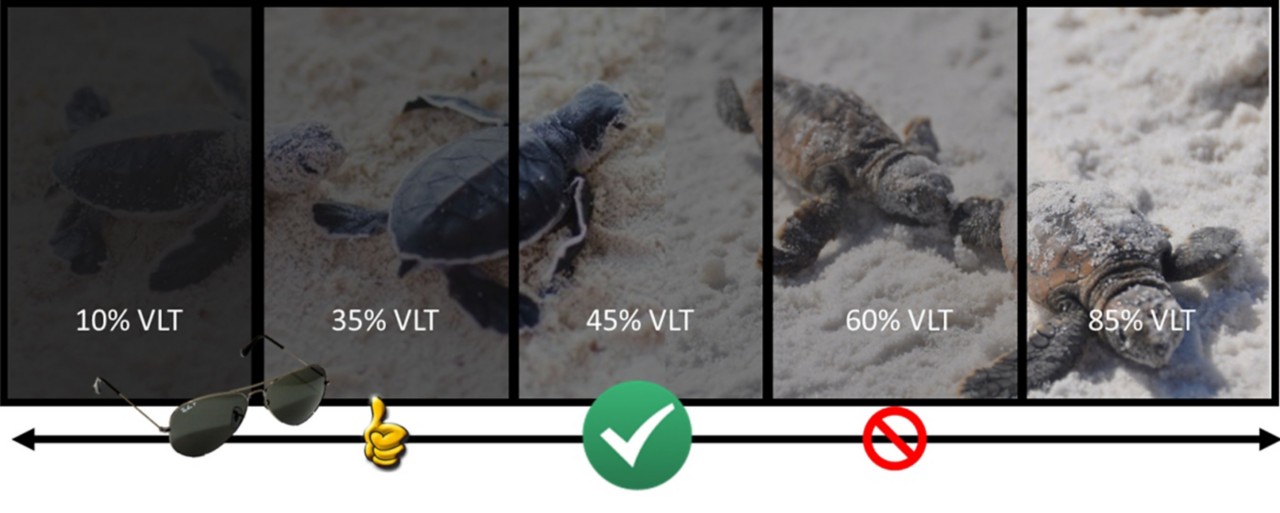

Visible light transmittance levels less than or equal to 45% are sometimes conceptualized as severe darkening of the glass.

Unless the glass is immediately adjacent to a high-light-transmitting panel or the glass is a non-neutral color, the perception may not be one of darkening. The light coming through the tinted glass may actually make the room more comfortable to the occupant due to a reduction of glare and solar heat transfer. Consider that most sunglasses for common use have a visible light transmittance between 10% and 30%, and the 45% visible light target does not seem dark at all! Some locations have proposed a reduction the allowable visible light transmittance from 45% to 15% because questions have arisen concerning the effectiveness of the 45%. Studies have been designed by the Florida Wildlife Commission and will be conducted to see if this reduction provides the assumed effectiveness. At the same time other variables such as enforcement of the current ordinance and proper implementation will need to be reviewed in order to avoid a drastic change if it proves unnecessary. A 30% drop in visible light transmittance will be noticeable to passerby’s during the day and to occupants at night. It will look as if the buildings are wearing a permanent pair of very dark sunglasses all year long. Results of the studies are expected to guide the adoption of lighting requirements.

Table 1 provides only a select few examples of colored laminated glass combinations prepared Vanceva interlayers, which are capable of meeting the “turtle code”. Thousands more can be designed to meet individual facility aesthetic and performance needs.

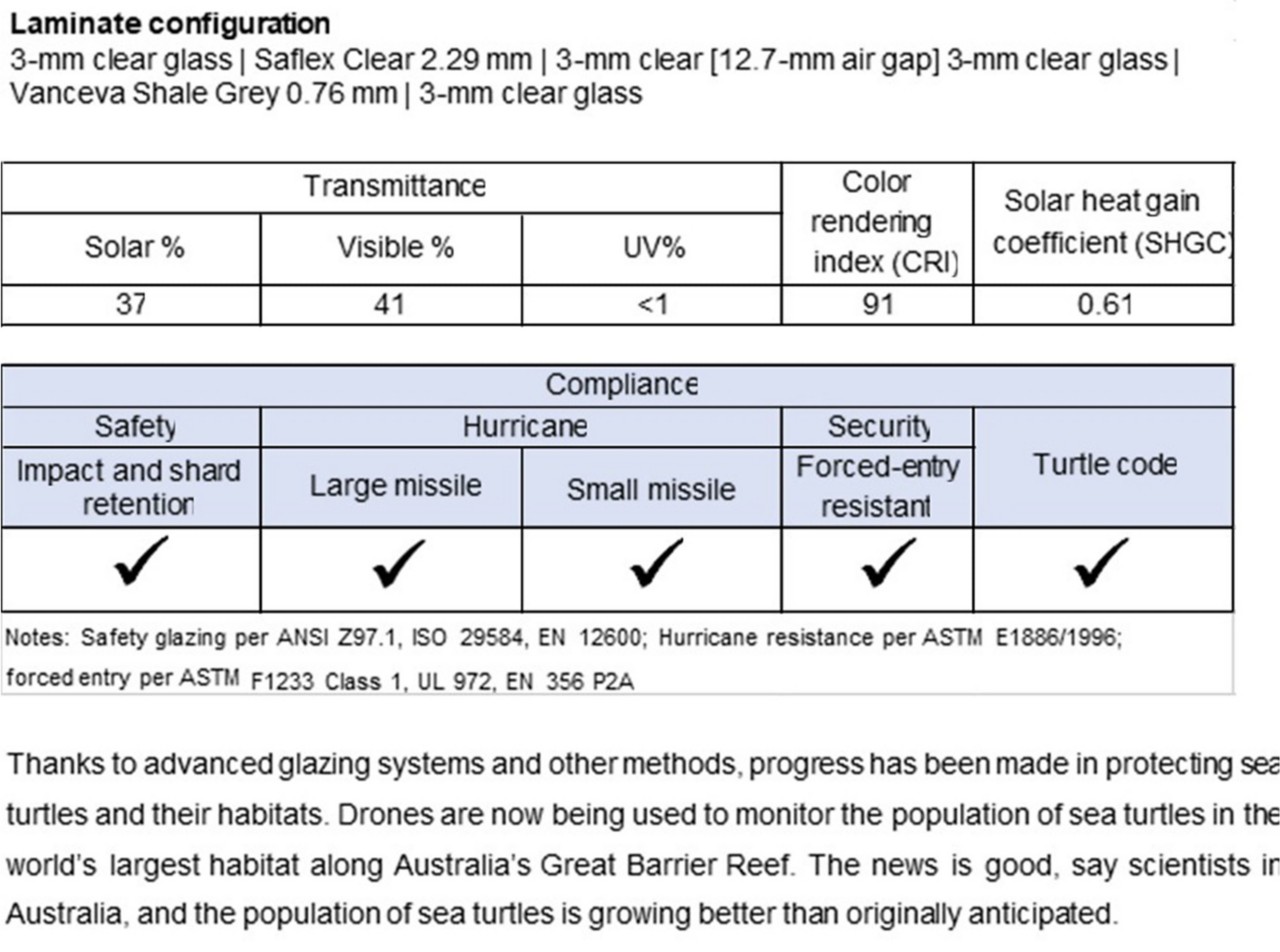

Laminated glass combinations

Laminated glass combinations can easily be incorporated as one or more lites of an insulating glass unit (IGU) for increased energy conservation, noise reduction, glass shard retention, and hurricane/cyclone protection. Table 2 provides a summary of performance characteristics for an IGU hurricane-resistant laminate based on one selected colored laminate combination; however, performance other than solar, optical, and thermal can be anticipated for other colors of the same configuration.